Load Capacity: 1-1500 tons

Speed: 20 m/min or as your needs

OEM&ODM: Support

Motors: PMAC / AC high efficiency motors

Wheels: Cast Steel /Polyurethane Rubber Wheel

Advantage: peculiar set-up makes the transfer cart save cost and operate more

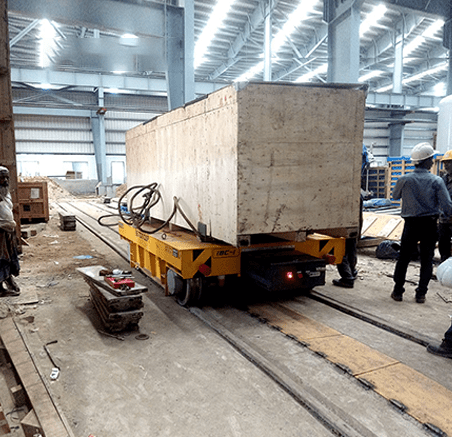

The Material Handing Rail Transfer Cart Runs Between Two Rails, And The Motor Is Used As The Driving Device. The Whole Transfer Cart Is Controlled By PLC. The Rail Transfer Cart Can Run Freely On The Track.

The Packing And Shipping:

The Main Body Of The Machine Is Packed With High-Quality Waterproof Plastic Cloth, The Electrical Parts Are Specially Protected, And The Spare Parts Are Packed In Standard Export Fumigation Free Wooden Boxes.

The Details Of Rail Transfer Cart:

1.Emergency Stop Button

2.Sound And Light Alarm

3.Intelligent Charger,And So On.

The Advantages Of Rail Transfer Cart:

1.Imported And Domestic Industrial Wireless Remote-Control Devices Are Optional;

2.Optional Matching Automatic Parking, And Alarming When Encountering Person 2 Meters Away.

3.The Largest Capacity Can Reach To 500t

4.AC+DC Electric Engine , Diesel Engine Or Pneumatic Engine

5.Low Noise And Do Not Pollute The Environment

The Application Field Of Product:

Rail Transfer Cart Is Widely Used In Machine Manufacturing, Warehouse, Metallurgy Factory, Etc. As A Workshop Internal Coordination Crane To Transport Heavy Objects Across.

| Type | BDG-2t | BDG-20t | BDG-50t | BDG-100t | BDG-150T | The BDGS Series Transfer Vehicle Is Powered By The Busbar.The Alternative Current Is Supplied Consistently To The Pulling Motor By Slide Knife Taken From Sliding Contact Line Through Electric Control System.The Sliding Contact Line Can Be Installed In The Middle Of The Tracks Or By The Outside Of The Tracks Or In The Trench Or Under The Roof Of The Plant. Positioning Fixture, Lift Platform, Clamping Device And Other Auxiliary Device Are Optional To Meet Different Demands On Various Occasions. The BHX Series Agv Transfer Vehicle Is Suitable In Inflammable Environment And In High Frequency. Customized design and manufacturing 1.Our professional design team provides | |

| Bated Load(t) | 2 | 20 | 50 | 100 | 150 | ||

| Table Size(mm) | Length(L) | 2000 | 4000 | 5500 | 6500 | 10000 | |

| Width(W) | 1500 | 2200 | 2500 | 2800 | 3000 | ||

| Heigth(H) | 450 | 550 | 650 | 900 | 1200 | ||

| Wheel Base(mm) | 1200 | 2800 | 4200 | 4900 | 7000 | ||

| Rail Inner Gauge(mm) | 1200 | 1435 | 1435 | 2000 | 2000 | ||

| Wheel Diameter(mm) | 270 | 350 | 500 | 600 | 600 | ||

| Wheel Quantity | 4 | 4 | 4 | 4 | 8 | ||

| Ground Clearance(mm) | 50 | 50 | 50 | 75 | 75 | ||

| Running Speed(min) | 0-25 | 0-20 | 0-20 | 0-20 | 0-18 | ||

| Motor Power(kw) | 1 | 2.2 | 5 | 10 | 15 | ||

| Battery Capacity | 180 | 180 | 330 | 440 | 600 | ||

| Battery Voltage | 24 | 48 | 48 | 72 | 72 | ||

| Running Time When Full Load | 4.32 | 4 | 3.3 | 3.2 | 2.9 | ||

| Running Distance for One Charge(Km) | 6.5 | 4.8 | 4 | 3.8 | 3.2 | ||

| Max Wheel Load(KN) | 14.4 | 77.7 | 174 | 343.8 | 265.2 | ||

| Reference Weight(t) | 2.8 | 5.9 | 8 | 14.6 | 26.8 | ||

| Recommended Rail Model | P15 | P24 | P43 | QU100 | QU100 | ||

360 degree motorized rotation without causing any damage to the floor.

Powered by storage battery, turning freely without any cable strings.

Controlled easily by pressing the buttons and speed controller.

High level automation(self propelled/steerable)

The largest capacity can reach to 100t

Safe parts are installed in the transfer cart(warning light, e-stop, buffer...)

Robust sturdy car frame

Please feel free to give your inquiry in the form below .We will reply you in 24 hours .

The Material Handing Rail Transfer Cart is widely used to transfer heavy cargoes of steel tube and pipes, coiled sheets and plates, steel bars, machine manufacturing pieces, metal forging and casting pieces, steel coils, building structural materials, galvanized coils and aluminum coils, other metal and steel heavy cargoes.

The Material Handing Rail Transfer Cart has a large load range from 1t to 300t. According to customer's special requirements, specific load ability is designed. And also, different table shape is designed according to different cargo shapes, for example coil car, ladle car, scissor lifting table cargo, etc.